Continuous commissioning: how “sparks” have pinpointed needles in haystacks for facilities managers

Building automation systems (BAS) have greatly improved our ability to manage building temperatures, adjust lighting levels, and control systems to maximize occupants’ comfort and save on energy costs. But with increased amounts of data to follow, pinpointing where equipment is failing can be like finding a needle in a haystack.

Sometimes, things break.

Facilities managers know this better than anyone. At any given time, there could be dozens or even hundreds of small (and not-so-small) failures in a campus’s HVAC system. The trick is locating the problem.

Building automation systems (BAS) have greatly improved our ability to manage building temperatures, adjust lighting levels, and control systems to maximize occupants’ comfort and save on energy costs. But with increased amounts of data to follow, pinpointing where equipment is failing can be like finding a needle in a haystack. So what if we had a way to identify problems faster?

It turns out we do. GreenerU uses a process of continuous measurement to support building energy analysis and control, using software that draws data from the building automation system and can be programmed to a building’s custom settings.

Why ongoing optimization?

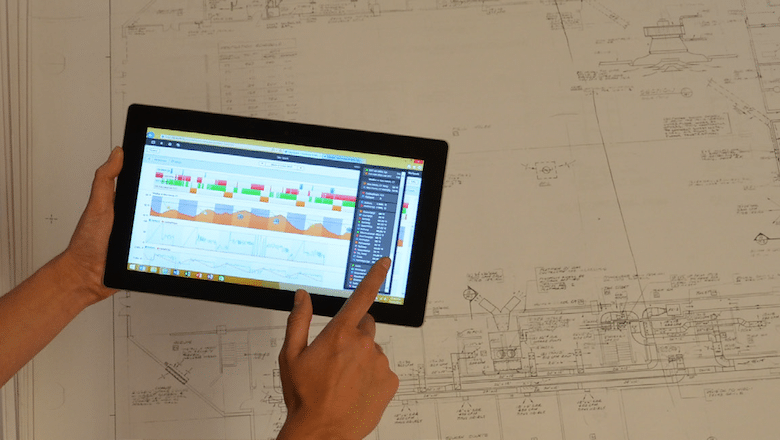

Enhanced building automation systems (BAS) can tell you when there’s a problem with occupant comfort. GreenerU’s continuous commissioning program will tell you when a system is wasting energy in the process of delivering occupant comfort. The program is built on the SkySpark platform, which draws data from the building automation system and manages and analyzes it, alerting facilities managers to problems that may otherwise go undetected.

SkySpark combines data streams with pre-programmed logic to identify problems and malfunctions as soon as they happen—before they waste energy or severely impact occupants. Using “if/then” logic and an easy-to-use interface, SkySpark first identifies problem areas and shows a “spark,” an indication of a problem. The spark tells building engineers where to investigate further and make fixes.

Three examples illustrate the value of SkySpark analytics on college campuses.

MacMillan Hall

Brown University’s MacMillan Hall was built in 1998. At 66,240 square feet, the building houses facilities for chemistry, geology, and environmental sciences research and instruction.

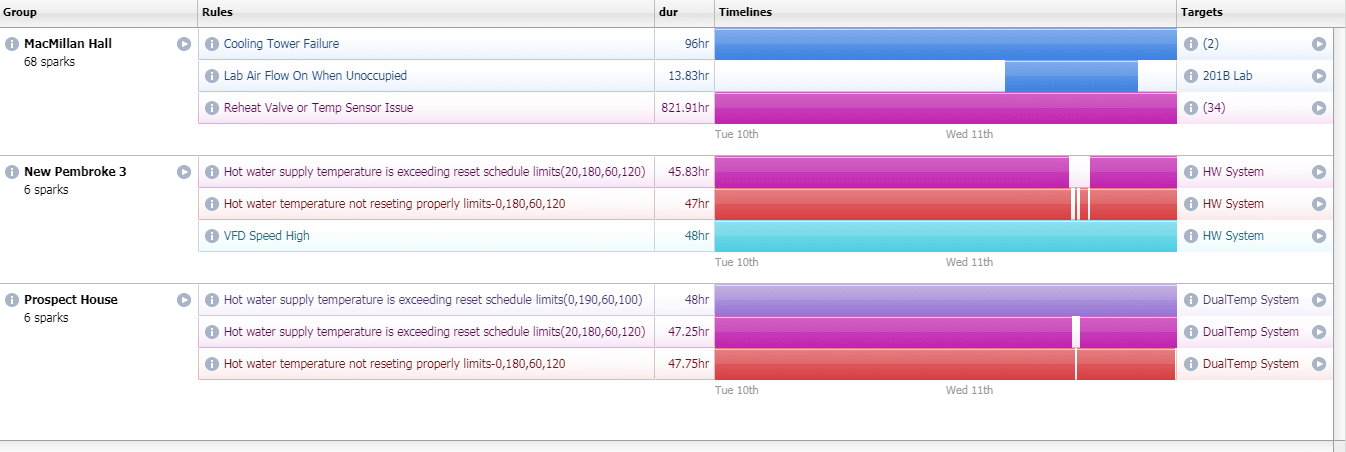

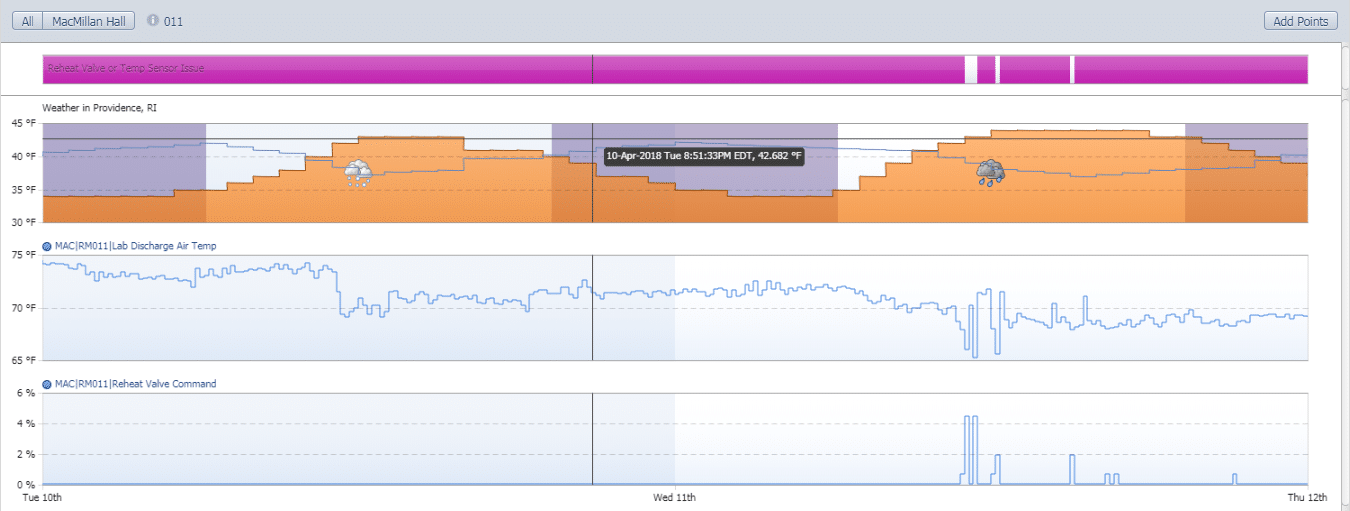

SkySpark software will alert building managers to issues with equipment connected to a building automation system by showing a “spark”—in the case illustrated below, a reheat valve sensor problem.

A closer look displays the problem: even though the reheat valves were closed, room temperatures were greater than the temperature of the air supplied in about 60 locations within the building.

What was happening? Three things: (1) the reheat valve movement did not match the commanded position; (2) the unoccupied schedule was not in place; and (3) the building’s hot-water temperature was set to 180˚F, instead of 95˚F as designed—in short, three conditions contributing to energy waste.

Luckily, the fix was easy. Operations immediately reprogrammed the stroke times of the valves; occupant scheduling was implemented; and hot-water temperature set points were corrected to 95˚F—which saved the customer $36,000 in annual energy costs.

Kemeny/Haldeman

At Dartmouth College, the Kemeny/Haldeman building was built in 2006 and consists of 94,000 square feet. The building features “smart” classrooms, labs, offices and common spaces; and houses the Ethics Institute, the Leslie Humanities Center, and the Dickey Center for International Understanding.

Dartmouth’s mechanical engineer wanted to know how often the bypass dampers were actually bypassing the heat wheel. Was energy saved using the bypass greater than the cost of eliminating the low-temperature tripping?

GreenerU used SkySpark to perform a quick analysis of the conditions and presented information in a way that facilitated easy decision-making.

In the end, Dartmouth’s mechanical engineer determined that the fix to correct the timing of when dampers should be open was more cost-effective than leaving the conditions that sometimes caused low-temperature tripping.

Biomedical Center

Brown’s Biomedical Center was built in 1969 with an addition built in 1990. At 106,635 square feet, it is used for medical academic, laboratory, and research functions.

An air handling unit—AHU 1—for the Biomedical Center had been simultaneously heating and cooling. Since the discharge temperature of the AHU was satisfied, the building automation system did not provide an alarm. But SkySpark noticed.

What was happening? The actuator was stuck open at 100%, all of the time—24 hours a day, seven days a week, 365 days a year. The fix was simple: the actuator was replaced.

The result was more dramatic, however. Chiller percent capacity dropped from 75% to 25% for an estimated annual savings of $91,000—a needle you don’t want to lose.

What needles are you looking for? GreenerU’s continuous commissioning program could be the right opportunity to get ahead of energy users on your campus before they get out of control. Call us at 781-209-5670 or email info@greeneru.com today to start a conversation about deploying SkySpark analytics on your campus.